Gastops is your equipment condition intelligence partner for the digital future

Online Wear Debris Monitoring System

The MetalSCAN wear debris sensor collects and processes real-time critical component condition data on oil-wetted components to give earliest warning of abnormal wear and predict Remaining Useful Life (RUL).

Laboratory

Services

Fluid, filter and material analysis services, providing leading indicators of machinery wear, fluid condition, and fluid contamination.

At-line Automated Metal Wear Chip Analysis

ChipCHECK offers comprehensive reports on fluid-borne metal chips, enabling operator crews to make the best maintenance decisions in minutes, directly at the flight line.

Press Release

Gastops Ltd. announced today it has joined forces with Pratt and Whitney Canada (P&WC) to conduct baseline testing, build the operational infrastructure and jointly develop diagnostic and prognostic services for P&WC’s breakthrough Oil Analysis Technology Program.

Article

Major North American Airline Cuts Delays & Costs with ChipCHECK

To a large commercial operator, every minute that the fleet is delayed means significant costs. Traditionally, finding wear debris “chips” during aircraft inspection resulted in extra monitoring and thousands of dollars of costs. ChipCHECK changed all that.

Application Guide

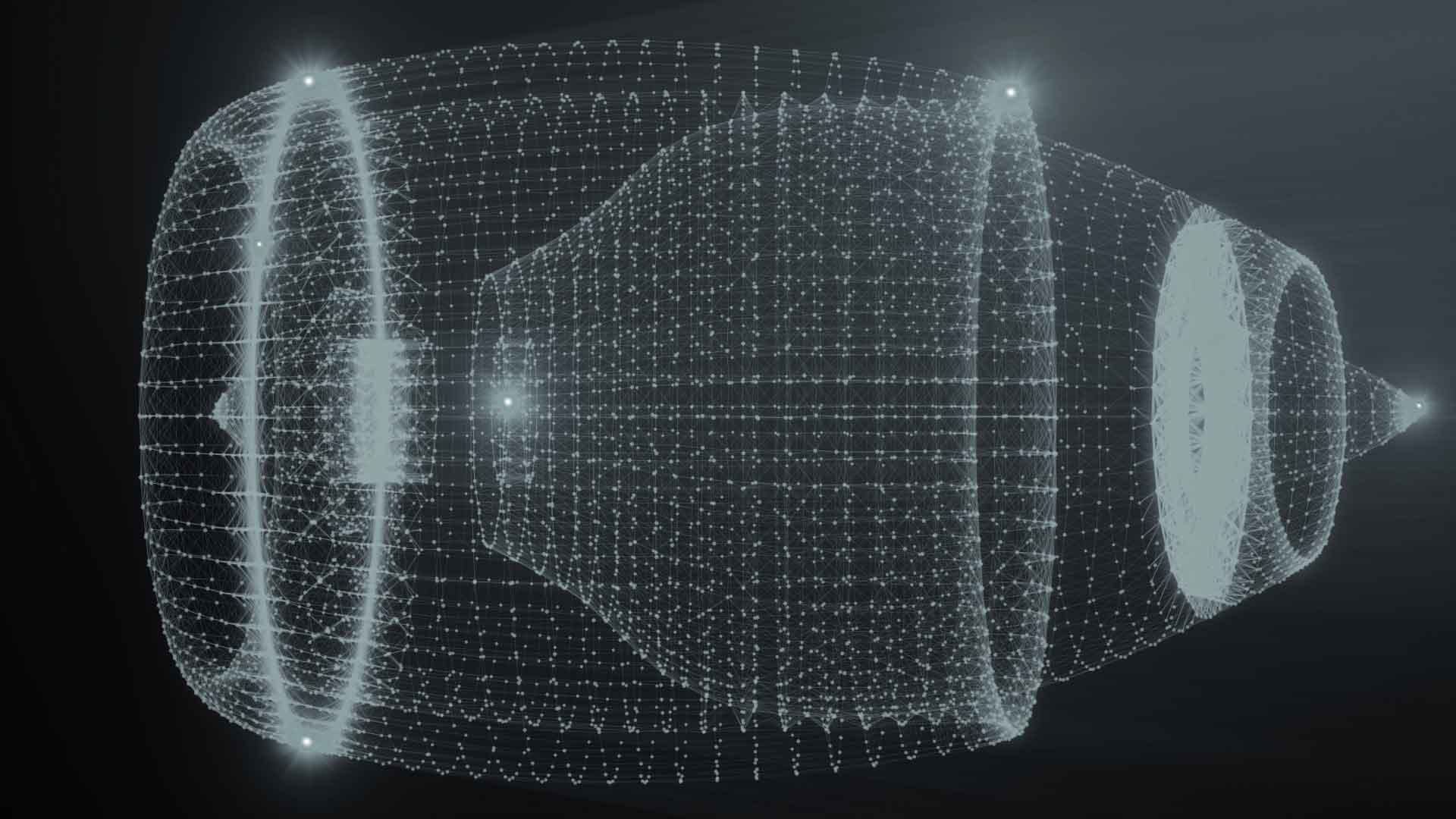

Airbus A320neo Application Guide

Real-time, in-flight damage detection. Designed for the Pratt & Whitney GTF commercial engine family, the MetalSCAN online oil debris sensor is integrated into the engine lubrication system.