Brochure

Gastops Solutions Overview

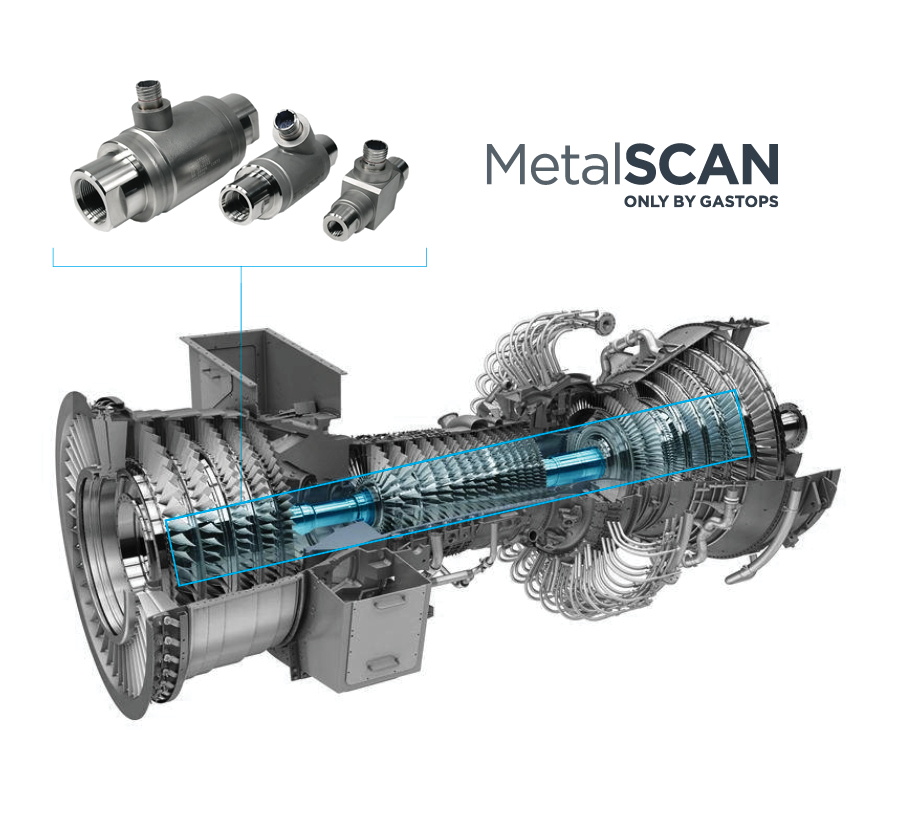

The MetalSCAN MS3500 Series of products provides the industry with online access to real-time condition monitoring data which enables the earliest reliable detection of component damage available on the market today.

Press Release

Gastops Partners with Seaspan for Advanced Propulsion System Analysis

Gastops, a global leader in intelligent condition monitoring solutions, is pleased to announce a significant contract award from Seaspan’s Vancouver Shipyards (Seaspan) to support the Canadian Coast Guard’s Multi-Purpose Vessel (MPV) Project.

Press Release

Gastops and Hanwha Ocean Sign MOU to Collaborate on Canadian Patrol Submarine Project

Gastops and Hanwha Ocean have announced the signing of a Memorandum of Understanding (MOU) to explore collaborative opportunities within the Canadian Patrol Submarine Project (“CPSP”) and other maritime initiatives, both domestically and internationally.

Article

DETECT PREVENT PRESERVE

Brennan West says the firm is now working with partners on the OCCM technology to achieve TRL-9 and to create new form factors for MetalSCAN to enable even simpler installation. The company is eager to bring their aviation proven MetalSCAN solution, and groundbreaking Oil Condition and Contamination Sensor to the naval marine and land vehicle space.

Article

Non-destructive Inspection Airman chips in to keep Cope West 23 going

“We’re monitoring the engine health, making sure that the engines are working properly,” Lara said. “If there was any problem with the engines, our ChipCHECK system would be able to catch any type of maintenance that would be necessary early on. So, it’s more preventative maintenance.”

Press Release

ChipCHECK chosen to support RCAF CH146 Griffon Fleet

Gastops is pleased to announce ChipCHECK’s selection on Bell Textron Canada’s program to support the Royal Canadian Air Force’s (RCAF) fleet of 85 CH146 Griffon helicopters, a multi-role military variant of the widely adopted Bell-412EP developed for the Canadian Armed forces. Seven ChipCHECK units have been procured to assist in maximizing equipment readiness, improve maintenance efficiency and reduce costs.

Press Release

Gastops Expands Support for Engine Test Cell Research and Development by Supplying MetalSCAN to Virtual Vehicle Research GmbH

Gastops is supporting Virtual Vehicle’s latest initiative in conducting high performance engine test cell research and development, supplying custom oil debris monitoring solutions with MetalSCAN.

Press Release

Gastops Receives Investment from Raytheon Intelligence & Space for Collaborative Research & Development with Pratt & Whitney

Gastops Ltd. announced that it has received an investment from Raytheon Intelligence & Space under Canada’s Industrial and Technological Benefits (ITB) program. The funding will support a multi-year research and development collaboration with Pratt & Whitney to develop the next generation of critical equipment intelligence solutions for commercial and military aircraft engines.

Brochure

MetalSCAN MS3500 Online Oil Debris Monitoring System Product Overview

The MetalSCAN MS3500 Series of products provides the industry with online access to real-time condition monitoring data which enables the earliest reliable detection of component damage available on the market today.

Press Release

Gastops Introduces the Connect Online Equipment Condition Monitoring Platform

Gastops today announced the official launch of Gastops Connect, an online subscription service that delivers critical equipment condition monitoring and analysis capabilities to those leveraging our condition monitoring sensor technology and solutions.

Brochure

Connect Equipment Condition Monitoring Service Overview

Gastops Connect collects, processes, and analyzes data from MetalSCAN sensors, combines it with your equipment controller data and third-party

data to create a comprehensive, real-time view of equipment condition accessible through any web browser device. It also provides an aggregated view across multiple sites for better analysis.

Article

Leveraging Condition Monitoring Expertise to Optimize MRO

Throughout the COVID-19 Pandemic the Military Aviation MRO segment has continued to see steady demand given the continuing need to maintain mission readiness. This steady demand has been challenged by the global supply chain disruptions that have impacted most industries, increasing the need for fleet operators to find trusted MRO partners who can combine leading edge technology with world class customer service to optimize their processes.

Brochure

Digital Twin: Model-Referenced Equipment Health Monitoring

Gastops has been developing physics-basedmodels of propulsion systems for over 30 years, pre-dating the dawn of ‘Digital Twin’. Our models have been used for system integration, condition monitoring, control system development, and more.

Press Release

Gastops Expands ChipCHECK Engine Coverage with Alloy Library Update

Gastops announced today the release of a major update to the ChipCHECK Alloy Library. The new library more than doubles the number of engine wear debris material types that can be detected by ChipCHECK.

Article

It’s All Systems Go! for Gastops’ Innovation in Oil Condition and Contamination Monitoring

Ottawa company invents breakthrough device that uses fluorescence spectroscopy to change how equipment maintenance is done.

Press Release

Boralex Selects MetalSCAN by Gastops for Geared Wind Turbines in France

Leading wind energy producer selects Gastops’ MetalSCAN MS3500 series sensors for gearbox condition monitoring systems on all new wind energy projects.

Press Release

Gastops Reports Strong Demand for their Latest MetalSCAN Condition Monitoring Sensor Series for Wind Turbines

With the MetalSCAN MS3500 series, Gastops sets the standard for oil debris monitoring technology for the wind energy industry.

Article

What Gastops Can Provide to the Wind Industry

The future is about combining machine intelligence and human capability to provide a full suite of real-time prognostics with tools and support for condition-based maintenance.

Article

Gastops: Maximize Asset Life

The future is about combining machine intelligence and human capability to provide a full suite of real-time prognostics with tools and support for condition-based maintenance.

Press Release

Gastops to Support USCG Ice Breaker Service Life Extension with Propulsion System Digital Twin Design

Gastops is pleased to announce that it has been selected by the U.S. Naval Sea Systems Command (NAVSEA) to provide a Propulsion System Dynamic Response Analysis (PSDRA) for the U.S. Coast Guard Cutter POLAR STAR. This contract has been made possible through a partnership with the Canadian Commercial Corporation (CCC).

Press Release

Gastops Receives IDEaS Funding for New Predictive Maintenance Technology

Gastops is pleased to announce that it has been selected by Canada’s Department of National Defence to contribute to the “All Systems Go!” Challenge, an initiative of the Government of Canada’s Innovation for Defence Excellence and Security (IDEaS) program.

Application Guide

MetalSCAN for Vestas Wind Turbines Application Guide

Reduce operating costs of wind energy production with critical component intelligence. MetalSCAN technology empowers wind turbine operators to effectively manage gearbox health issues using oil debris monitoring.

Article

Major North American Airline Cuts Delays & Costs with ChipCHECK

To a large commercial operator, every minute that the fleet is delayed means significant costs. Traditionally, finding wear debris “chips” during aircraft inspection resulted in extra monitoring and thousands of dollars of costs. ChipCHECK changed all that.

Back to News & Resources

Back to News & Resources